the-wearness-collection

RECYCLED & BIODEGRADABLE TIMELESS FAVORITES

Our own collection. Every three months we launch a new item. The unique aspect of our Capsule Collection is its consistently sustainable concept and its commitment to the principles of the Circular Economy. Pieces that convince with timeless designs and leave no waste on the earth.

Read More

Our motivation for our own small collection came with a question we keep asking ourselves: how can we get away from wasting resources and mountains of discarded clothes.

1.2 billion tonnes of CO2 are currently emitted annually by the textile and clothing industry, more than by flying and cruise ships combined. According to calculations by the non-profit organisation Water Footprint Network, around 2,500 litres of water are needed to produce just one T-shirt, and as much as 8,000 litres for a pair of jeans. One hundred billion articles are now produced every year - twice as many as 20 years ago. Fast fashion is only worn four times on average. According to calculations by the Ellen MacArthur Foundation, a truckload of clothing ends up in the landfills every second.

It may sound paradoxical - but we decided to create even more fashion - our own collection according to the principles of the Circular Economy. Moving away from fast fashion and disposable fashion to a collection that is made from recycled materials and is biodegradable. A collection that is timeless and not bound to fast trends and where every item can become a classic. A new garment is launched every three months, all matching and yet each piece stands on its own.

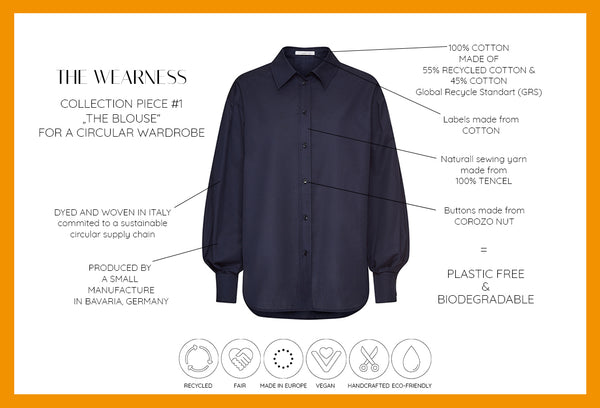

#1 THE BLOUSE

"The Blouse" is characterised by an elegant design that also stands out for its special details: the balloon sleeves and overcut shoulders create a voluminous cut, while the box pleat at the back is a special eye-catcher. However, besides the aesthetic factors, it's the inner values that count the most: the garment is made exclusively from natural materials and is 100% biodegradable. Made of cotton, consisting of 55% recycled cotton and 45% cotton. (Global Recycle Standard GRS). The fabric comes from the Italian company Canclini, who is committed to a sustainable and circular supply chain. All labels are made from 100% cotton. The sewing yarn is made of 100% Tencel. The buttons are made from corozo nuts.

#2 THE DRESS

"The Dress" is an elegant shirt-blouse dress in midi length with a pointed collar, wide cuffs and a box pleat at the back.

Special is the material: the dress is made of REFIBRA™. It is breathable, with perfect moisture absorption, antibacterial and bleach-free.

The REFIBRA™ fibre is made from upcycled cotton scraps and a mixture of wood chips. Roughly speaking, it is a man-made fibre made from regenerated cellulose. Thus, materials from garment production waste are used and the raw material is processed into new TENCEL™ lyocell fibers. Not only does this reduce the amount of raw materials needed, but REFIBRA™ is also compostable and biodegradable in water and can also be recycled again.

The fibre was developed by the Austrian company Lenzing. The company has virtually no such thing as "waste products": almost all solvents and emissions can be recovered or degraded. Water consumption in Lyocell production is about 80% lower than in conventional cotton processing. In addition, Lenzing has committed to using 100% renewable energy in its production processes. The wood species used - eucalyptus, pine, spruce, acacia, birch, beech, aspen and maple - are FSC or PEFC certified and are processed entirely in Heiligenkreuz, Austria.

Besides the fabric, all other components are made of natural materials and are biodegradable. All labels are made from 100% cotton. The sewing thread is made of 100% Tencel. The buttons are made from Corozo nuts.

CIRCULAR FASHION

The concept of the circular economy and the cradle-to-cradle principle is based on nature and biological cycles - because these leave no waste. The result? Garments that are completely biodegradable.

The endless biodegradable cycle

During the development process, we sought advice from the Berlin start-up "Circular.Fashion" to make our own designs consistently sustainable. The company offers various tools to promote sustainability in the fashion industry.

"In addition to a workshop on circular and cradle-to-cradle principles, we were able to use a fabric database to find the perfect materials: the fabric made from recycled cotton, yarns made from Tencel, buttons made from stone nut, inserts and labels made from cotton - all plastic-free!", says Julia Zirpel.

We also decided to produce in Germany - in order to communicate easily with partner companies and to keep transport routes as short as possible in order to save CO2.

Karolin Helou at the manufacture close to Passau, Germany

Of course, we want our blouse to be worn as long as possible - because every single item of clothing gets sustainable after 30 times of wearing. Love it, share it, sell it, repair it - or simply send it back to us. We bring them back into the cycle.